Umshini Wokudayela Izithelo Nemifino we-LG-350

Imingcele Yezobuchwepheshe

a.Ububanzi bophephela:350 mm

b.Motor : Y112M-44KW

c.Umthamo: 1000-2000kg/h

Isisindo: 350kg

d.Ubukhulu: 1100x 1100 x1600mm (ubude * ububanzi * ubude)

e.Indawo yokufaka okuphakelayo: ukuphakama kwe-inlet ukusuka endaweni eyi-1310mm yokungena engu-450×360mm

f.Imbobo yokukhipha: ukuphakama kwe-outlet kusuka endaweni engaphansi engu-490mm yokuthekelisa engu-195×60mm

Isimiso sokusebenza

Ukusuka ezintweni ezingavuthiwe ukuya ku-hopper ukuya ekujikelezeni kwe-propeller, umkhiqizo ngaphansi kwesenzo

wamandla amaphakathi, eduze nohlangothi lwangaphakathi lwegobolondo langaphandle, nama-propeller blades phakathi kokusikwa

ummese, kanye nombese wokusika kusukela emnyango olungisekayo wangaphambili wendlu ukuze uphume, ukushuba kuka

umkhawulo womnyango wokuvuleka kwe-slice blade kunqunywa.Sika ngocezu umhlahlandlela ekujikelezeni kwe-roller yokudla, i-feeding roller kanye nokuzungezisa okuhlobene kwe

i-auxiliary feed shaft, izothunyelwa ku-disk slice cutter shaft, imikhiqizo isikwa ibe yimichilo, bese

ngqo ekujikelezeni kommese, usike isikwele sawo, unxande noma obunye ubukhulu obusethiwe.Izici: sika phakathi kwepheya lama-feed rollers, ungavimbeli ekusikeni, inqubo.

Ukusika usayizi

Lungisa ukuvuleka komnyango wezindlu, ukuvuleka kwesivalo sediski, bese ubuyisela ummese

umhlangano.Inganqunywa ngobukhulu obuhlukahlukene.1. Susa umhlangano wommese wediski, umhlangano wokuphakelayo osizayo kanye nokuhlanganiswa kommese, lungisa

ukuvulwa komnyango wegobolondo, futhi ingasika ucezu oluyi-1.6 ~ 11mm.2. Faka i-disk knife assembly, i-axiliary feeding assembly, ngaphandle komhlangano wommese, ingasika i-strip, i-wire, i-block shape.3. Faka zonke izisiki

Ungasika: 3 * 3 * 3, 3.5 * 3.5 * 3.5, 4 * 4 * 4, 5 * 5 * 5, 6 * 6 * 6 * 6, 7 * 7 * 7, 8 x 8 x 8, 10 * 10 * 10 tee

Futhi ingasikwa: 3 * 3 * (1.6 ~ 11), 3.5 * 3.5 * (1.6 ~ 11), 4 x 4 x (1.6 ~ 11), 5 * 5 * (1.6 ~ 11), 6 x6 x (1.6) ~ 11), 7 * 7 * 1.6 ~ (11), 8 x 8 x (1.6 ~ 11), 10 * 10 * (1.6 ~ 11)

Kanye nobude obude obuyi-19, 25, 30 noma obukhululekile bemicu kasilika, ingahlanganiswa ukusika ubukhulu obuncane.

ngaphezu kwama-cubes ayi-10 adingekayo.4. Ngokusho inhlanganisela ithuluzi ungasika ukushuba of ezahlukene shape square, strip elingunxande, ubude strip kungaba 15, 20, 25, 30 noma khulula ubude.5. Susa umhlangano wommese, futhi impahla ingasikwa ibe yimichilo yocingo olude yamahhala.6. Sika izingcezu ezi-3x3, 6x6, wabelane ngokucaciswa okufanayo (3) umhlangano wokuphakelayo osizayo, isigubhu sokudla.

nokuhlanganisa amazinyo ekama.Ukusika izingcezu ezingu-4×4, 8×8, ukwabelana ngokucaciswa okufanayo (4) ukuhlanganiswa kwesiphakeli esisizayo, i-feed roller kanye

ukuhlanganisa amazinyo ekama;

Ukusika izingcezu eziyi-5x5, eziyi-10×10, ukwabelana ngokucaciswa okufanayo (5) ukuhlanganiswa kwesiphakeli esisizayo, i-feed roller kanye

umhlangano wekamu.

Faka uhlelo lokusebenza

I-1.Indawo yokufaka impahla kufanele ibe ngendlela yokuthi okokusebenza kuzinzile futhi kunokwanele

indawo yokuhlanza nokugcinwa kalula.

2. Xhuma amandla ukuze i-propeller izungezise ngokuphambene newashi lapho ibukwa embobeni yokuphakelayo

futhi isekelwe ngokufanele.

3. Ngaphambi kokuqala idivayisi, kubalulekile ukuqinisekisa ukuthi yonke imizimba yangaphandle kanye nemikhiqizo ku

indawo yokudla isusiwe, futhi idiski yesandla ivumelaniswa nesondo lebhande ukuze kuqinisekiswe

ukuthi azikho izidumbu zangaphandle emshinini wokusika.

4. Qala injini, yenze ifinyelele esimweni sokusebenza ngesivinini esigcwele, izinzile futhi iyunifomu kusuka echwebeni lokuphakelayo

ukudla.

Qaphela:

(1) ungavumeli izinto zakwamanye amazwe njengamathuluzi, amatshe, amabhodlela nezinye izinsimbi endaweni yokudla, ukuze ungalimazi izingxenye zomshini wokusika.

(2) Ungaqhubeki nokudla ngokweqile, ukuze ungalayishi kakhulu injini, ukuminyana kwechweba lokuphakelayo noma ukusika

ithuluzi libhajwe, okuthinta ikhwalithi yomkhiqizo.

(3) Ungafaki isandla sakho emlonyeni wesiphakeli, ukuze ungasindi ingalo.

(4) Lapho okokusebenza kusebenza, ipuleti lekhava noma ipuleti lokuvikela akufanele likhishelwe kulo

gwema ukulimala okubi kakhulu.

(5) I-blade ebuthuntu kufanele ilolwe ngaphambi kokuba isetshenziswe futhi.

Isondlo

Umshini uqukethe abasiki abacijile, izingxenye ezijikelezayo kanye namandla kagesi aphezulu.Lapho ushintsha imininingwane yokusika kanye nokugcinwa kwemishini, ukunikezwa kwamandla kufanele kunqanyulwe futhi kukhiywe

kuqala.Ipuleti lekhava nepuleti lokuvikela kungasuswa ngemva kokuqinisekisa ngokubonakalayo ukuthi okokusebenza kumiswe ngokuphelele, ngaphandle kwalokho ukulimala okubi kungase kubangelwe.

(A) ukunakekelwa kwansuku zonke

1. Khipha i-cover plate kanye ne- guard plate ukuze kugcinwe zonke izingxenye zemishini.

1) Khipha ipuleti lekhava, ipuleti elivikelayo kanye nesembozo somhlahlandlela wesigaba ukuze ulondoloze ukuhlanganiswa kokudayela

futhi ugcobe umshini.

2) Hlukanisa i-hopper yokuphakelayo ukuze ugcine idivayisi yokusika.

3) Hlukanisa ipuleti lonogada ukuze ulondoloze ingxenye yokudayela kanye nengxenye yokushayela.

2. Ukuhlanza: nqamula futhi ukhiye ugesi, susa wonke ama-cover plate, futhi uhlanze kahle.

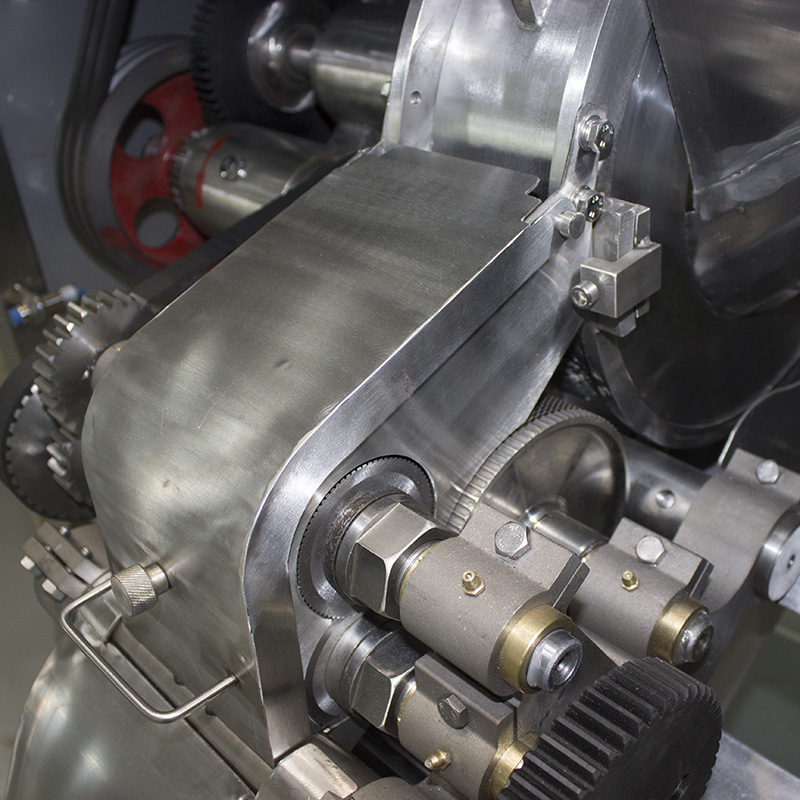

3. Ukugcotshwa: Izindawo zokuthambisa zethusi eziyi-8 zalo mshini zifakwe uwoyela wethusi wemabula

ama-nozzles (njengoba kuboniswe esithombeni).Amafutha okudla kufanele afakwe kanye amahora angu-4 ~ 6 wokusebenza, futhi

ukusebenza kumele kugcinwe kuvumelana nezimo.Ukufakwa okungahleliwe kokugcwalisa i-refueling: ibhotela elijwayelekile elingu-400g lebha yokucindezela

isibhamu.Izingxenye zamagiya zivame ukugcotshwa.

(B) Ukugcinwa kwezingxenye ezibalulekile nezingxenye

1. Ukuqaqa, ukuhlola, ukuhlanzwa nokufakwa kwedivayisi yokudayela.

1) susa

a.Nqamula futhi ukhiye ukunikezwa kwamandla, susa iphaneli yangaphambili, i-groove engenalutho, umhlahlandlela wesigaba

ikhava, ipuleti lokuvikela, bese ususa ibhande elihambisanayo.

b.Khipha i-blade assembly: khulula isikulufu sokulungisa ku-blade shaft, ubambe i-blade assembly, futhi ukhiphe i-spindle negiya.

c.Hlukanisa i-disc cutter shaft: susa ibhande le-synchronous, khulula izikulufo zokulungisa zegiya lenayiloni, susa igiya lokudlulisa i-strip cutter, khulula izikulufu zokulungisa zeshafu yommese, ubambe umhlangano wokusika idiski ngesandla esisodwa, bese ukhipha idiski. i-cutter shaft nomunye.

d.Susa i-axiliary feed shaft: khulula isikulufu sokulungisa se-auxiliary feed shaft, ubambe

i-auxiliary feed shaft assembly ngesandla esisodwa, bese ukhipha i-auxiliary feed shaft nge

okunye.2) Ukuhlolwa kokuhlanza:

Hlanza kahle, hlola ijenali kanye nendwangu yethusi ukuthi izoguga, futhi ukhiphe amazinyo ekama

kanye ne-feed barrel uma kunesidingo.3) Hlanganisa kabusha:

A. Uma ufaka i-shaft, i-shaft kumele ikwazi ukuphushwa futhi ijikelezwe ngokukhululekile.B. Faka isigubhu sokuphakelayo: beka isigubhu sokuphakelayo phakathi nendawo yezisekelo eziseceleni ezimbili, futhi

igebe phakathi komkhawulo owodwa kanye nobuso bokugcina be-copper liner cishe ngu-0.1mm.Phusha i

feed isigubhu shaft futhi uqinise izikulufi zokulungisa (qaphela ukuthi izikulufo ezimbili zokulungisa kufanele ziwe

emgodini we-shaft).

C. Faka umhlangano we-disc cutter: phusha ingxenye ye-disc cutter shaft kubakaki oseceleni, beka umhlangano we-disc cutter phakathi kwama-lining amabili ethusi, i-disc blade ibekwe.

phakathi nendawo yesilinda sokuphakelayo, bese uphushela i-shaft phakathi, ukuze igebe phakathi kwesiphetho esisodwa nobuso bokugcina bomugqa wethusi libe ngu-0.1mm, qinisa okubili okungaguquki.

izikulufo (naka ukuwela emgodini we-shaft).D. faka i-auxiliary feed shaft assembly: uhlangothi lwezingxenye zeshaft yesiphakeli esisizayo

ama-scaffolds, umhlangano wokuphakelayo osizayo phakathi kokubili kwethusi, yenza i-carbon blade yokuphakelayo okusizayo phakathi kwe-disc blade, bese ingena ku-eksisi yokuphakelayo okusizayo, ohlangothini olukude

ukuvunyelwa kohlangothi lwethusi kucishe kube ngu-0.1 mm, izikulufo ezimbili ezilungisiwe (qaphela ukuwela emgodini womgodi).e.Faka ikamu: Faka ikamu le-comb shaft endaweni emaphakathi phakathi kwediski

blade, phendulela i-shaft yekama phezulu kuze kube yilapho ithiphu yekama ithinta ibhulokhi yesikhala se-disc cutter, bese uqinisa isivalo sikabakaki oseceleni ngamandla amaphakathi.f.Faka umhlangano wokusika: cindezela ingxenye yokusika kubakaki oseceleni, beka umhlangano wokusika phakathi kwezihlahla ezimbili zethusi, bese ufaka i-cutter shaft ukuze igiya lihambisane negiya le-disc cutter shaft.Ukucaciswa phakathi kokuphela kwesisiki kanye nobuso bokugcina besihlahla sethusi cishe ku-0.25mm, futhi qinisa izikulufu ezimbili zokulungisa (naka umgodi

we-shaft).

2. Umhlangano wokuhlanganisa i-disc cutter, ukuhlanganiswa kwesiphakeli esisizayo kanye nokuhlanganiswa kwe-blade

1) umhlangano we-disc cutter esibambi sokusika ukuze ukhweze i-gasket ekuqaleni, bese ufaka enye i-disc blade (i-blade yommese kufanele ibheke ohlangothini olufanayo) kanye ne-gasket (izici ezihlukile zokuvala, ukuqala ukushuba kwesikhala phakathi kwe-gasket nommese kanye ummese

ihluke, ukunakwa okukhethekile kufanele kukhokhwe lapho kususwa umhlangano, ama-gaskets ngokusho kwe-oda langempela elikhona, hhayi ukuphazamiseka), futhi ekugcineni qinisa i-clamp nut.

2) umhlangano wokuphakelayo osizayo: kusibambi sokusika ukuze ugibele isiqalo ngemuva kwe-gasket (engasho lutho, ubukhulu be-gasket yokuqala buhlukile), ifakwe ummese we-disc, bese ifaka i-gasket kanye nensingo yokudla ehambisanayo, ngokushintshana ku-shaft owokugcina uthi

ye-disc blade kanye ne-gasket yokuphela (osesithombeni), lapho uqinisa nati, ukugcina i-carbon blade yokuphakelayo okusizayo ukuqondanisa kwamazinyo ayisithupha.

3) ukuhlanganisa ummese: 3, 3.5, 4, 5, 6, 7 mm ucezu lwe-butyl lommese luphakathi kwendandatho emibili egxilwe kusiphathi samathuluzi, lapho ukufakwa kuzoqala ngokuthola indandatho ekugcineni kwesikulufu esiqinile, kuyenze eduze kwesihloko endaweni yokuphumula yommese, bese ucindezela ngokucophelela ummese endaweni, faka u-a

indandatho yesibili, kancane kancane qinisa nut, kodwa hhayi kakhulu.Ukufakwa kwezisiki eziyisi-8 ~ 10mm kufanele kwenze abasiki babekwe ngokuqinile phansi kwesihlalo sommese ukuze kuqinisekiswe ukuthi isinzwa esiyi-0.038mm asikwazi ukufakwa esikhaleni esingemva kommese.